Starting with squaring up a block of cast iron.

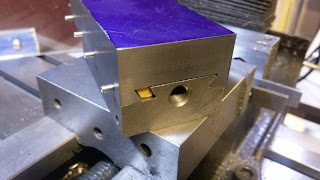

First run on the little fly cutter I just made. I did the big material removal with a large carbide insert face mill and then took the final cut with the fly cutter

Good surface finish with the fly cutter.

Instead of milling 1/8" off of the side of the block, I elected to get sketchy with the band saw.

Roughing out the slot for the dovetail.

This big 3/4" rougher can remove a lot of material fast.

Engage dovetail cutter! This cutter was actually too large for the cut. I ended up cutting on both sides during the first pass. Not a horrible thing, but not ideal.

6-32 threads in cast iron...always fun.

Test fit onto the base with the brass gib.

New compound in the foreground, old one in the back. I added fillets to the left side and front to prevent chips from building up under the tool post. I went with four gib screws instead of three like th original.

When roughing the cut away, my roughing mill pulled from the collet a little bit. I ended up having to blow out the tolerance to make it flat. Luckily not a critical dimension. If this had been for someone else I would have started over.

My ball mill ALSO pulled out during its next to last cut. Not pleased. But no one to blame but myself.

When I was setting up to make this part, I completely forgot to get the 4mm tap to do the holes for the dial on the end of the slide. I'll have to wait to do that until I order more tools and material. So this is done for a week or so.

No comments:

Post a Comment